How to launch your idea into space

with help from Surrey Space Centre's free SpaceCraft initiative

The space industry is thriving. News of attempts to reach the Moon hit the headlines regularly, and SpaceX launches rockets several times a week. We rely daily on the benefits from satellites orbiting us, some of them smaller than a shoebox.

Space: a £3bn business in Surrey and Hampshire

Once, just NASA and Roscosmos ruled space.

Now, it's a huge industry open to businesses of all sizes.

The space sector is a core part of the Surrey and Hampshire economies, generating over £3bn of income and £1.64bn of export revenue.

More than 5,500 people in the region work in the sector at big, international names like Airbus or Surrey Satellite Technology Ltd (originally a spin-out from Surrey Space Centre) and numerous smaller businesses, all the way down to micro-SMEs like Atout Process.

Surrey Space Centre at the University of Surrey has long been at the heart of the ever growing, thriving sector, conducting cutting-edge research and developing much-needed higher level skills among our students, whether undergraduates, postgraduates, PhD candidates or industry-based learners.

The SpaceCraft programme, making it easier to enter the space industry

Although more businesses are breaking into the sector, sending an instrument to space is still highly complex. The University of Surrey’s SpaceCraft programme, supported by the UK Space Agency, means help is now available. It opens the doors of the renowned Surrey Space Centre to budding entrepreneurs, providing facilities and advice to companies wanting to get into space.

Industry experts

The space engineers at Surrey Space Centre have spent their careers researching, developing and making instruments for space, seeing them launch, and using the data sent back to Earth. They are experienced at negotiating the many steps involved, including securing a spot on a rocket launch, designing, creating and assembling components, conducting tests to ensure instruments will survive the arduous journey to space and its hostile conditions, and communicating with satellites in orbit.

They have the expertise needed to create small to medium satellites and instruments, and the equipment required too. Here they highlight what’s involved with sending an instrument to space.

Design and development

Once you’ve identified a solution to a problem, the Surrey Space Centre experts can talk it through with you and point you towards others who can help, like the team at Space South Central, which is the regional space cluster led by the universities of Surrey, Portsmouth and Southampton, supported by the UK Space Agency. They can help identify funding opportunities, put you in touch with space companies and offer wider support.

Building a prototype

To demonstrate your idea, you’ll need an operational prototype. If it’s going to space, it’ll hitch a ride alongside other instruments, some of them highly sensitive.

You’ll therefore need to make your prototype under special conditions in a clean room, ensuring it’s free of dust, grease and other contaminants.

Surrey Space Centre has a large clean room and other maker spaces, and its resident experts can advise on processes and materials to meet the strict requirements of organisations like ESA.

Core testing

Launch is expensive and arduous, so you’ll always need to prove your instrument will survive. Surrey Space Centre has the equipment needed to conduct the required tests.

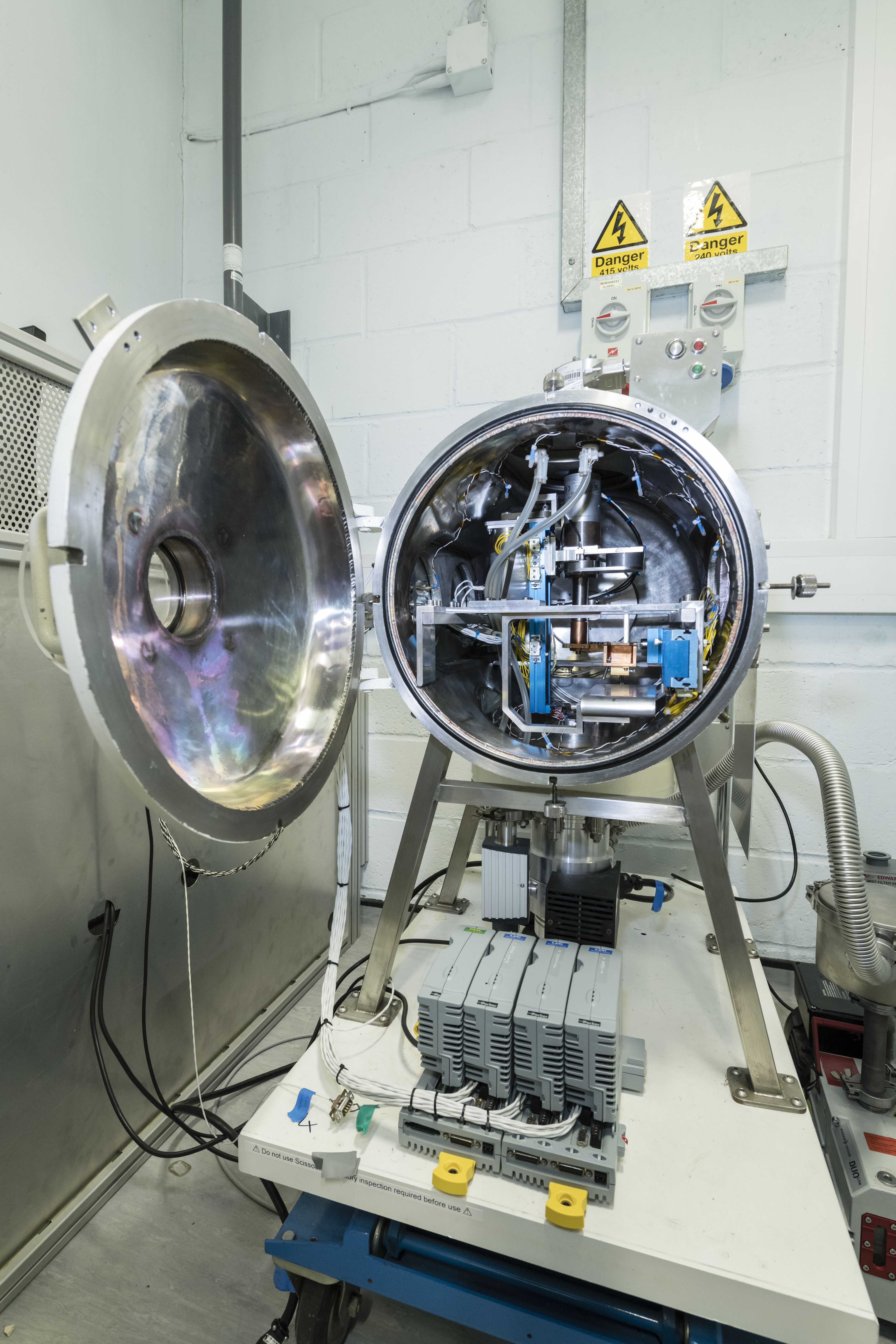

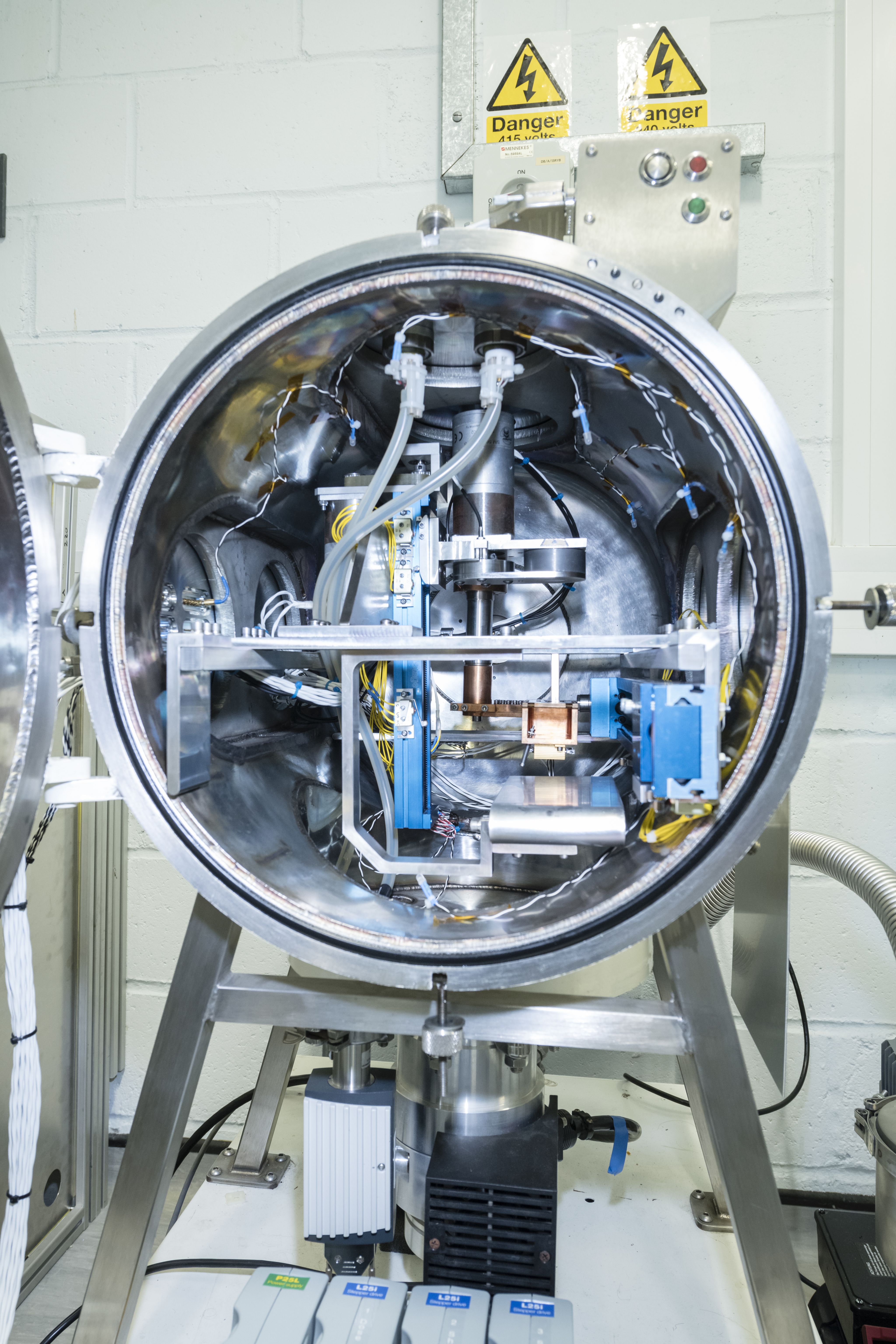

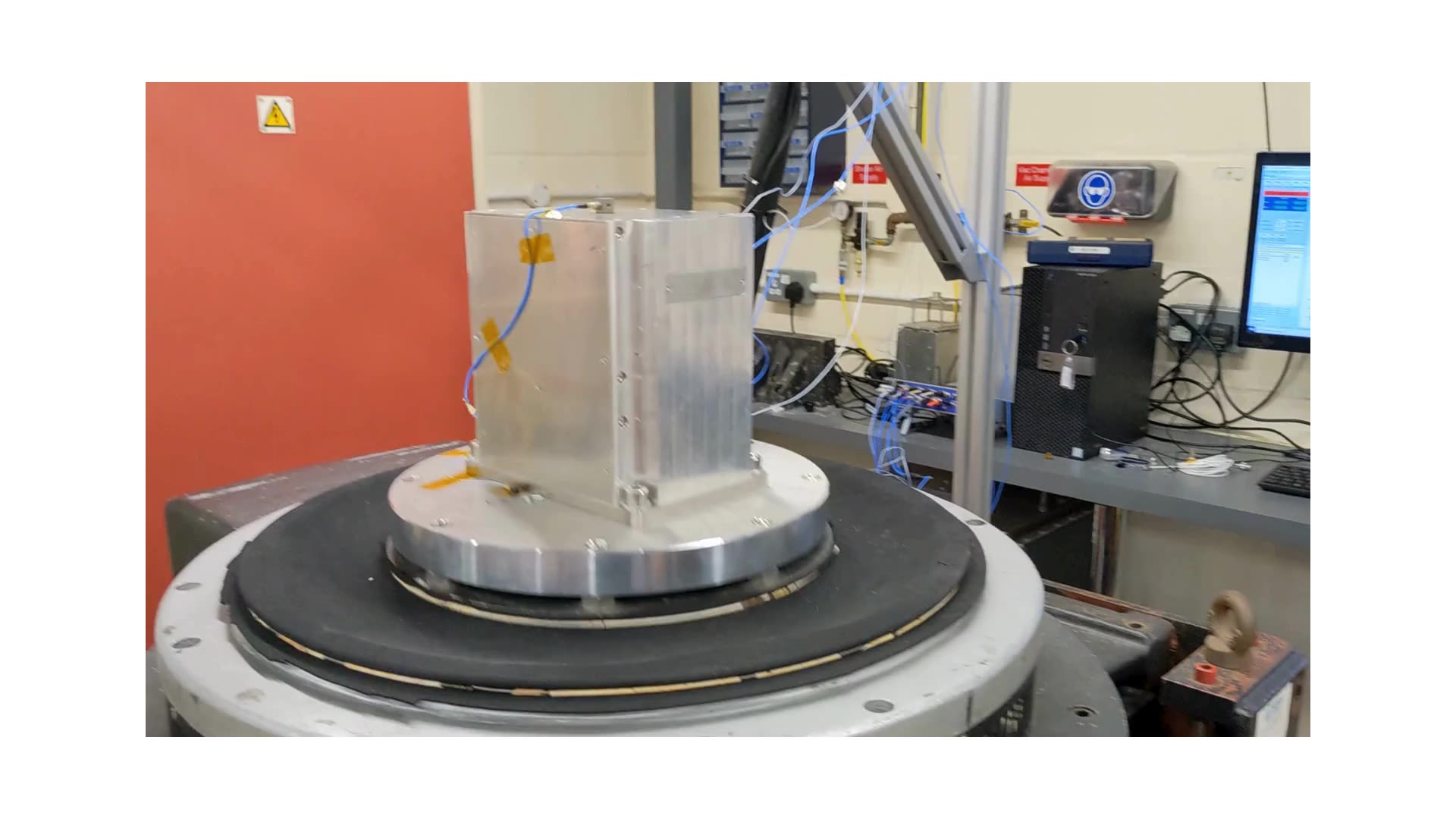

“The two most important tests use the vibration table and the thermal vacuum chamber,” says Paul Morris, SpaceCraft’s Chief Engineer.

The vibration table mimics the forces exerted during launch. “You’ve seen the stresses put on astronauts and the rigorous training they endure to cope with it. This is the equivalent for instruments.”

The thermal vacuum chamber puts instruments through their paces in the extreme heat and cold. “There’s no convection in the vacuum of space, so heat transfer happens purely through radiation and conduction,” explains Paul. “It means things get hot in very different ways, so it’s a vital test in a more realistic environment.”

Radiation testing

One of the areas of expertise at Surrey Space Centre is space weather and its impacts. Coronal Mass Ejections from the Sun and particle events cause surges in radiation which can damage equipment on Earth’s surface, while instruments in orbit are even more exposed.

Surrey’s space engineers can advise on which insulators to choose and can help test instruments which might be sensitive to bursts of radiation.

The Centre’s unique Realistic Electron Environment Facility, or REEF, closely replicates in-orbit conditions and can deliver the total dose of radiation an instrument is expected to endure during its mission.

Launch and beyond

Surrey Space Centre’s ground station and control room offers in-house mission command facilities.

It can monitor your instrument during launch and its journey to orbit.

Once it is in situ and operational, the ground station offers telecommand (operating instruments in space and adjusting satellite movement) and telemetry (receiving data from your instrument).

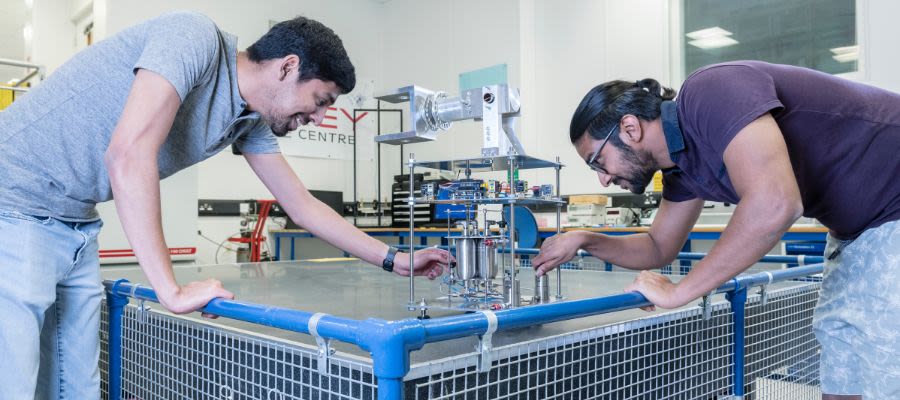

One company using our facilities through SpaceCraft is Atout Process Ltd, whose Smart Tank for Space – or SMARTTS – will accurately measure how full a tank is in zero gravity.

"We have already benefited enormously from SpaceCraft to develop our revolutionary new propellant tank gauging technology and prepare for its first in-orbit test,” says their COO, Richard Foster-Turner. “As a very small space company the support and facilities provided have been vital.”

Atout secured a contract with the European Space Agency to demonstrate their SMARTTS on the International Space Station and plan to use Surrey Space Centre to prepare their instrument for launch in 2025.

Space is an exciting, growing sector with opportunities for a range of businesses, including those who haven’t worked in the area before. Inspired? Got an idea for your own space business? Get in touch: SpaceCraft@surrey.ac.uk